- VALUE CONTRIBUTION

Supply Chain Risk & Crisis Management

I’ve successfully built and implemented award-winning supply chain risk management programs for more than 10 companies since 2008

- SUPPLY CHAIN ROBUSTNESS

Supply Chain Risk Management

Our day-to-day business is determined by constant supply bottlenecks, uncertain supply chains, geopolitical risks, and unstable suppliers. Apart from common sense, banks, customers and the LkSG require a formal Supply Chain Risk Management, as do the Quality Management systems (IATF 16949, ISO 9001).

Taking responsibility for your supply chain is more critical than ever. A transparent, robust supply chain is a competitive advantage and a core task of a modern Supply Chain function. Supply Chain Risk Management is neither time-consuming nor complex, but it needs to be done!

With more than 10 years of experience in successful projects, I support you in setting up a practical Supply chain Risk Management approach and help you secure your supply chains. Well-known automotive, pharmaceuticals, mechanical engineering, and public transportation clients have entrusted me with their Supply Chain Risk management. German Procurement (BME) and Logistics Associations (BVL) and the Forbes Magazine have repeatedly awarded and recognized these projects as groundbreaking.

Building a robust risk management in just two steps:

- Request our free Guideline. On 15 pages, you will learn from practical examples how to successfully introduce a customized Supply Chain Risk Management and anchor it deeply in your daily Procurement and Supplier Management operations.

- Start with our Supply Chain Risk Management workshop to quickly strengthen your organization and your supply chain robustness and simultaneously integrate the requirements of the current Supply Chain Due Diligence Acts. You will learn about the most important building blocks and success factors, avoid common mistakes, and receive a customized roadmap for implementation.

- OUR WORK

I know how to build an effective Supply Chain Risk Management and I will guide you

I support you on your journey to resilience. I have been setting up Supply Chain Risk Management programs since 2008. In SMEs and global corporations. I know the powerful levers and the success factors as well as the stumbling blocks. Due to my extensive experience in dealing with crises, I provide targeted crisis support. Together we will set up your customized Supply Chain Risk Management. Identify alternative suppliers, both manually and with the support of artificial intelligence, to secure your supply chains and your supply. I help you build a tailored Risk Governance, build and manage crisis teams, communicate with your suppliers, and help you to implement an insolvency management process.

Guideline: "How to Get Started with SCRM"

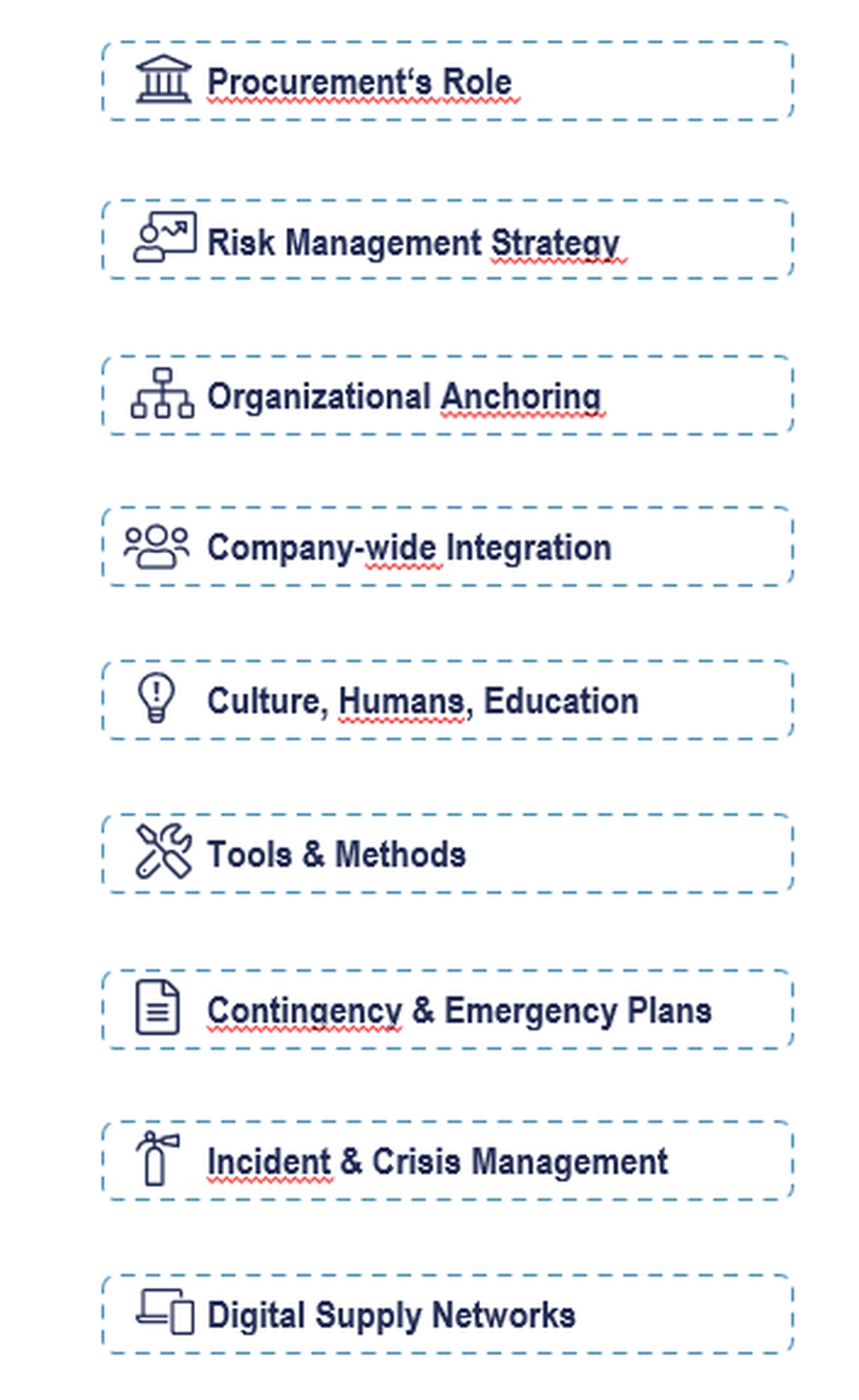

Learn how to successfully introduce customized Supply Chain Risk Management and anchor it in your daily Procurement and Supplier Management:

- Assessment of your current maturity level and derivation of a tailored plan

- Developing a tailored Supply Chain Risk Strategy

- Implementation and daily operations

- Operating Model, Governance Framework, agile crisis management

- Stakeholder integration

- Establishing processes and contingency plans

- Fostering awareness and building comptencies

- Integration: category & supplier management

- Selection and Implementation of digital solutions

These measures will strengthen your supply chain and protect you against future risks.

Awarded Solutions

BME Excellence in eSolutions 2015 – Risk Management

BVL Logistikpreis 2016 – Umfassendes digitales Logistikkonzept

FORBES Magazine, 2015 & 2022, New Solutions for Risk Management

Workshop Supply Chain Risk & Ingrity Mgmt.

Identify development potential and build or strengthen your Supply Chain Risk Management based on best practices. Incorporate the requirements of the Supply Chain Acts.

Not every crisis can be foreseen or prevented! But it can be professionally managed, and damage can be contained. We prepare you for this. We work with you to understand gaps and potentials and review your established strategies, structures, emergency plans, and processes. We evaluate your organization for risk awareness, routines, and skills. And assess your starting point for the Supply Chain Act. Our goal is to enable you to take your supply chain risk management to the next level quickly and agile.

- Establish a comprehensive Operating Model and Governance Framework

- IATF 16959 & DIN ISO 9001 compliance

- Compliance with the LkSG and CSDDD

- Reosurces, Policies, Processes to be establised

- Stakeholder integration (incl.suppliers)

- Learn and adapt best practices

- Crisis management tools and contingency plans

- Digital Supply Chain Risk, Sustainability and Compliance solutions

- Get your tailored SCRM matchplan

Start immediately! The intensive 1.5- 2 days will give you a clear directive on how to ambitiously develop your Supply Chain Risk Management and implement the requirements of the different Supply Chain Acts. It pays off, guaranteed. Satisfied customers include Autoliv, Weidmüller, cellcentric, Stiebel Eltron, and many more.