Customer Projects & Uses Cases

Effective & Sustainable - for SMEs and corporations

Use Cases

Health Care/Clinic

Interim Leadership & Organizational Development

Shipping & Maritime Services

Interim Management, Organizational Development & Transformation

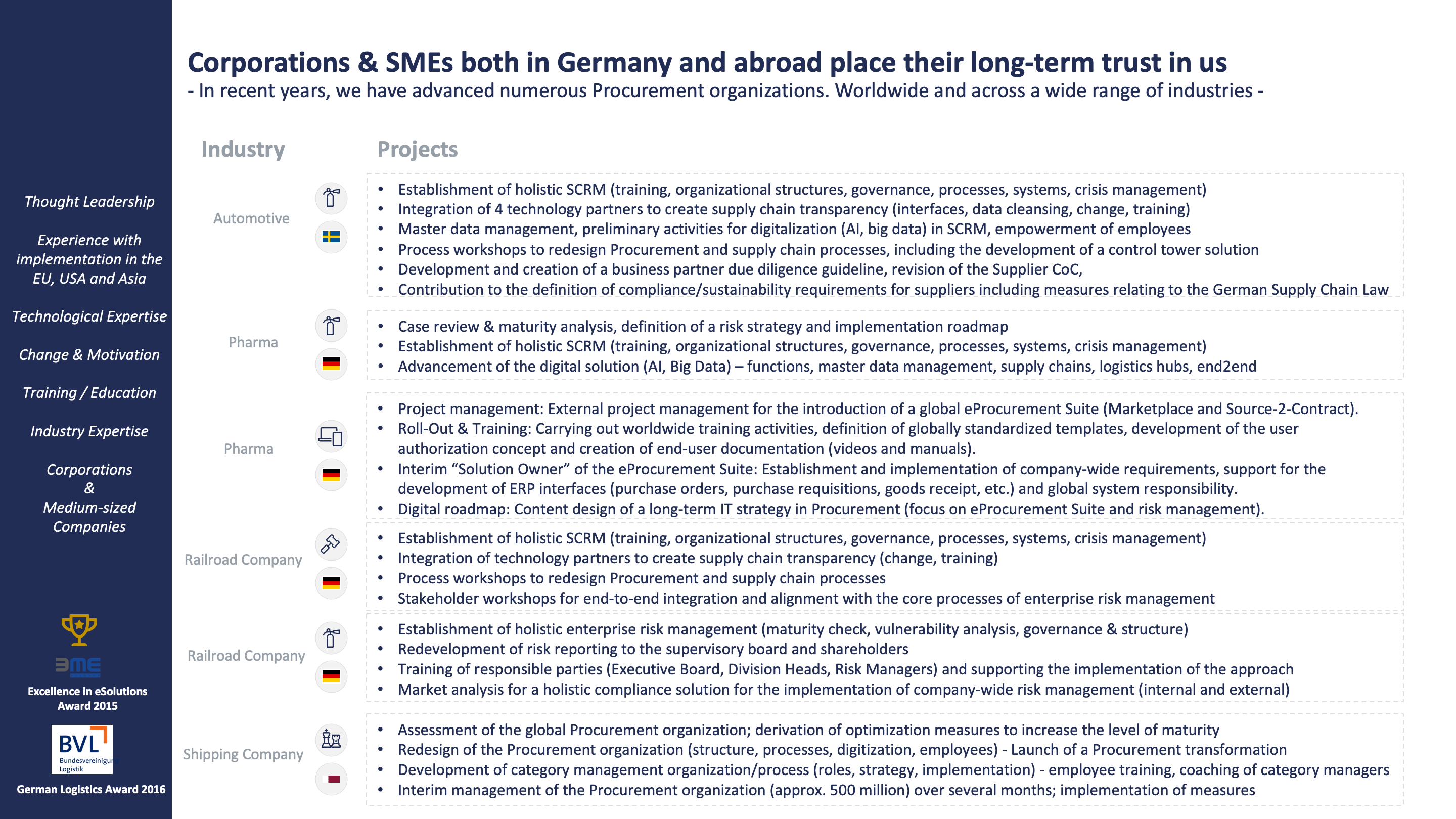

Automotive

Establishing a global Supply Chain Risk Management Function and Approach

Various: Pharmaceutical, Railway, Contstruction, Material Handling

Organisationsentwicklung, Transformation, Excellence, Risiko & Compliance Management, LkSG

Agricultural Machines

Organizational Design, Transformation, Procurement Excellence

Automotive

Organizational Design, Supply Chain Risk Management, Procurement Digitalization

My Global Customers

Thomas Schnadt

Co Founder of INNOSourcing GmbH, former CPO of UBS and Credit Suisse

I’ve been working with targetP! for some time now. I have experienced Jan as an experienced Procurement executive who brings plenty of „Horsepower“ to the ground by executing and implementing innovative as well as proven solutions. Jan is a fundamental contributor in terms of repositioning Procurement as well as in extensive employee development. targetP! masters the theory and knows how to bring it to practice.

Heiko Schwarz

Managing Director riskmethods GmbH, Munich/Boston

targetP! is our partner to call about procurement excellence and people development. They are no-nonsense, straight-to-the-point procurement leaders with a strong entrepreneurial mindset. targetP!’s emphasis on connecting theory and practice gives them an impressive breadth of knowledge that’s much wider than the typical range of consultants. They took the time to understand our business needs and then delivered results fast using a hands-on approach that helped us tremendously to increase our capabilities in the area of procurement.

Brian Zydel

VP-Industrial Controller; AGCO Corporation

Prior to joining the company the procurement organization was regionally divided, focusing on price and delivery as their value proposition. Jan and his team led the transformation of procurement into a global commodity-based organization, improving the methods employed and developing the necessary processes within the global team resulting record highs in material savings and visibility in the overall value proposition of procurement. I would recommend Jan and the team to anyone trying to move the bar in their procurement organization.

Akram Iswaisi, CPA

Group CFO and Head of Investments at Milaha

Jan and his team have done a phenomenal job in helping transform our procurement department, He has definitely brought world class know-how and expertise to the team. It’s a long journey but we are definitely on the right track.

Dr. Ulrich Piepel

Former CPO at RWE AG & innogy SE

Congratulations Jan-Henner Theißen to your wonderful and very successful journey with targetP! Your are one of the best procurement experts I have ever met. And your strength as a consultant is to apply pragmatic solutions at large, medium and small sized procurement organizations which really work show a sustainable and fast impact. Your ideas are shaped by creativity and knowledge, and your advice uses a language which is understandable for management as well as for operations. Keep up the great work! All the best for the next years!